Modbus OPC Server Suite – MatrikonOPC OPC Servers

How to connect to Modbus devices using OPC

Of all the industrial protocols out there, Modbus is one of the most popular.

Its open protocol, easy implementation, and basic featureset all combine to

make it a well used protocol. This article will explain how to

connect Modbus to OPC

and the differences between basic communications and more advanced

telemetry communication between Modbus and OPC

Basic media options:

Serial (either RS232 or RS485)

Ethernet

More advanced connection options:

Radio

GPRS

Satellite

dial up modem

Protocols

Modbus

Modbus RTU

Modbus on TCP

Enron Modbus

Modbus Plus

Daniel Modbus

Bently Nevada Modbus

Registers

Data in Modbus is grouped in registers

0x: read/write tags that can be on or off. Sometimes called "coils",

"digitals", "relays", or "booleans" Address range from 00001-09999

1x: read-only tags that can be on or off. Sometimes called "coils", "digitals",

"relays", or "booleans" Address range from 10001-19999

3x: Read only tags. 16 bit sizes by default. Also called input registers

4x: Read/write tags. 16 bit sizes by default. Also called holding registers.

Interpreting different registers

What if I’m using floats, 32 bit "wide" registers, unsigned integer, swapped

word order, ASCII strings, etc? With these registers, most OPC Servers offer

letter suffixes or some other way of denoting that the OPC Server should treat

that tag differently. With the

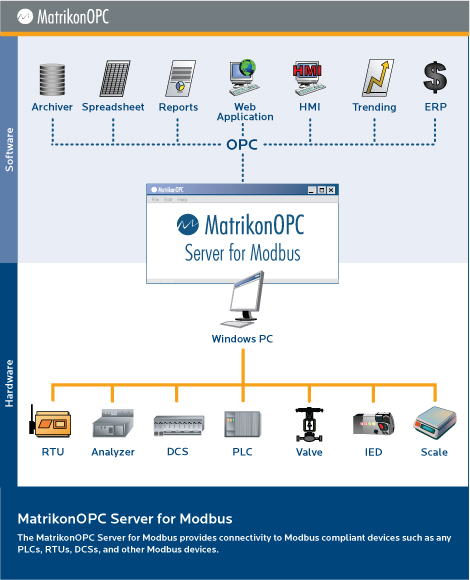

Matrikon OPC Server for Modbus,

as an example, a paired register for a 32 bit floating-point real OPC Tag might

look like this: TestChannel.TestDevice.4:34P

Master/Slave Control

Many people out there know that OPC Clients are typically embedded in

applications that need to have control over communications. OPC Servers are

typically built for applications that do not need to control the

communications. Many protocols out there, such as Modbus, also follow this

philosophy. Modbus is Master/Slave, just like OPC is Client/Server. Usually,

you want your OPC Server to act as the Modbus Master, and relay the control

down the line. But sometimes, you’ll want your device to have more control over

the communications such as if your device was to "phone home" in an alarm

condition. In these instances, you’ll need your OPC Server to act as a Modbus

slave. Most OPC Servers do not support slave mode, so if you need it, be sure

to ask your vendor.

Telemetry

The problem we’re going to run into with advanced connections is that OPC

Servers are just passive translators. With a complex telemetry environment,

where we communicate with many RTU’s or PLC’s over high latency, low bandwidth,

shared communication links; we’re going to need an OPC Server with more brains.

These "brains" are more advanced timing and polling options. A good

Telemetry SCADA OPC Server

should support round robin polling, interrupt/demand polling, and have many

advanced timing parameters to account for different delays or polling times.

Multiple Masters

One of the differences between the two is that you can have more than 1 OPC

Client connected to each OPC Server, whereas you don’t usually want 2 Modbus

Masters talking to the same Modbus slave. This can be a problem if you’re using

redundant OPC Servers or multiple Master applications. Be sure to talk to your

vendor on alleviating these issues in your application if these are an issue.

For more information on Modbus, see Modbus-IDA at

modbus.org

|